Electric operators attached to the gate panels are usually the most cost effective means of automating swing type gates as there is less ground work required compared to that of installing an underground motor unit. There are many different sizes of gate mounted electric drives and offered in 3 basic type.

1. Articulated arm type motor which is like a hinged arm pushing and pulling the gate leaf.

This is the cheapest form of electric motor generally and is limited in its power drive so used generally on smaller gates with less forces and weights. This operator type is very useful when there is limited space between the gate and the piers or walls either side as it can fit into tight spaces.

2. Electro mechnical motor drive units which have varying degrees of power output for use with different gate sizes and weights. Cheaper than hydraulic but not as quiet or powerful generally.

3. Hydraulic piston gate operators which are usually the best for larger or heavier gates and have the potential for the best power drive. These are best used on gates which have high usage and also require the best hold closed facility. The torque in these gate operators is usually far higher than other types.

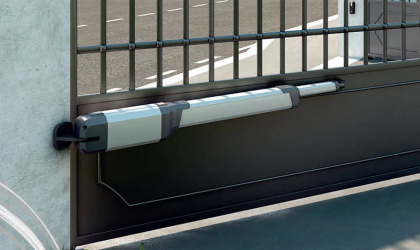

Rear surface mounted rams are installed to the rear face of an inward swing gate, generally it is best to have the inside or back of the gate running flush with the back face of a pier or posts horizontally mounted operating power arm for electric gates - wood, timber, steel, aluminium gates in order that the correct geometry can achieved.

It is always best to discuss the proposed fitting position with our surveyor prior to the constriction of brick or stone piers as this can avoid any potential costly mistakes should the set up geometry not be achievable. Also remember if starting from scratch it is always best to have steel box section gate posts for sheer stability and strength. They can obviously be clad in brick or stone once installed or left and painted or dressed in timber as an option too.

Rear Surface Mounted Rams are suitable for Timber, Steel and Aluminium gates.

We recommend that the Bottom and Top Hinge Brackets incorporate an adjustable feature for setting the gates up and to allow for any future adjustment requirements.

Surface mounted drives are generally not unattractive and can be specified for ornamental steel gates or timber gates – fully boarded or open pale designs. Different brands and models have different sizes and case designs so it is best to check if you are concerned in any way.

Often these units come in a light aluminium finish, in some cases they can be over painted without affecting the manufacturer’s warranty.

It is possible on small to medium width gates to have very good self locking system by the motor units themselves holding the gate leaves closed. Obviously the bigger the width the more this becomes an issue and if you do want more security we would incorporate an electronic lock on the gate leaves to hold the gate locked at low level.

All gate motor drives have an anti crush feature which is adjustable on the units and control board. There is a balance to strike here so the gates do not simply always think there is an obstacle because the gates are in a windy area and the wind replicates an obstacle. Safety with any electric gate system is the most important factor and this is usually dealt with using infra red safety beams along with anti entrapment sensors in crucial zones on the gates.

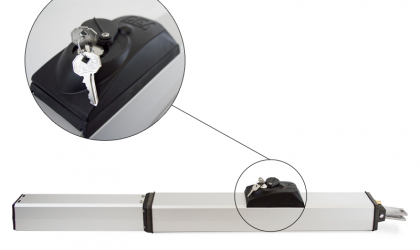

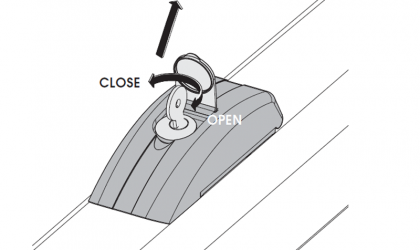

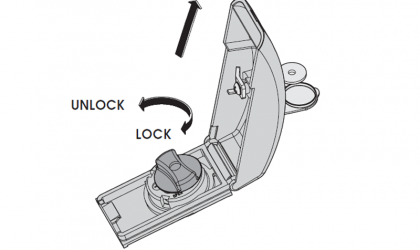

All electric gate motors incorporate an emergency manual override feature so that gates can be overridden in the event of a power failure or emergency. The units themselves can have a key locked facility where there is a release device to either disconnect the hydraulic drive or the motor drive whilst the gate is opened or closed.